FAQ / Frequently Asked Questions – Alternator

How do I know which alternator fits my tractor or construction machine?

You can find the correct alternator by matching the OEM number, machine model and engine type. At Olsson Parts, you can search directly using the OEM number or filter alternators by amperage, connections and “Fits to” lists. Always check the mounting points, pulley type and connector type before purchasing.

Can I upgrade to an alternator with higher amperage than the original?

Yes, as long as the cables – especially the B+ cable – are sized to handle the higher charging current. A more powerful alternator may be necessary if the machine has additional lights, electronics or other electrical consumers.

What symptoms indicate that the alternator is failing?

Common signs include the battery not charging, flickering lights, the battery warning light on the dashboard, unstable electronic behaviour or unusual noise from the alternator. A whining or scraping sound often indicates worn bearings.

How long does an alternator last on a tractor or construction machine?

Lifespan varies depending on workload, environment and maintenance. An alternator that is kept clean, has the correct belt tension and operates in a healthy electrical system can last many thousands of operating hours. Harsh environments, incorrect belt tension or overloading significantly shorten its lifespan.

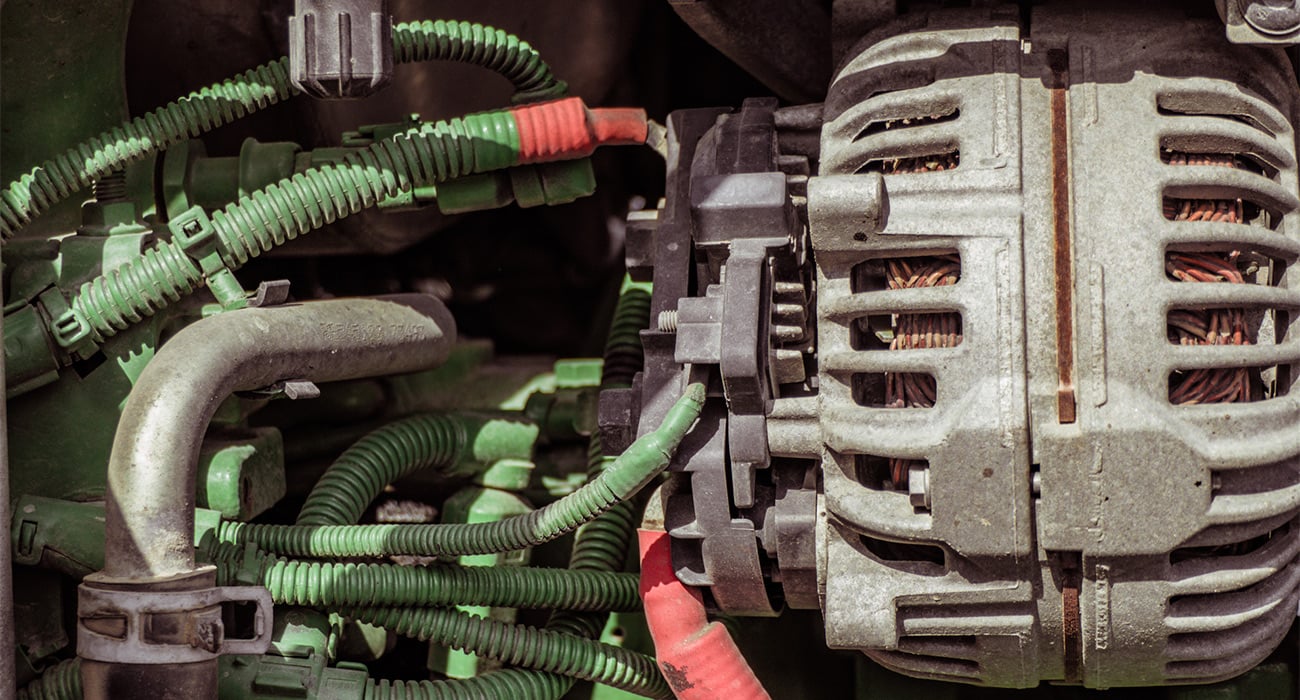

How do I maintain my alternator to extend its lifespan?

Keep the alternator clean from dust and dirt, check the belt condition and tension, ensure proper grounding and verify that all cables are intact. Avoid overloading the electrical system and replace worn bearings to prevent failures.

How do I test if the alternator is charging correctly?

Measure the voltage across the battery terminals with a multimeter while the machine is running. A functioning alternator should charge at around 13.8–14.5 volts. If the value is lower, there is likely a charging issue.

Do I need to replace the alternator immediately if the battery light turns on?

Not always – the issue may be with the wiring, regulator, belt or grounding. However, the battery light always indicates a charging problem and should be checked immediately to avoid downtime.

What is the difference between a standard alternator and a heavy-duty alternator?

A heavy-duty alternator is built for tougher environments and longer operating periods. It has more robust bearings, better cooling and often higher amperage. It is recommended for construction machines with high load demands or continuous operation.

Do I need to replace the belt when changing the alternator?

It is not mandatory, but recommended. A worn or poorly tensioned belt can cause charging problems even with a new alternator. A new belt ensures optimal performance and reduces the risk of issues.

How do I find the correct alternator if I can’t locate my OEM number?

You can search by machine model, engine type or use the filters at Olsson Parts. If information is missing, you can also identify the alternator by its mountings, pulley and connector type – or contact customer support for assistance.