900 packages a day

Kaj’s little workshop at home on his farm near Ellös has grown. By 1981, it had grown so much that the entire operation had to move to new premises in the nearby industrial area.

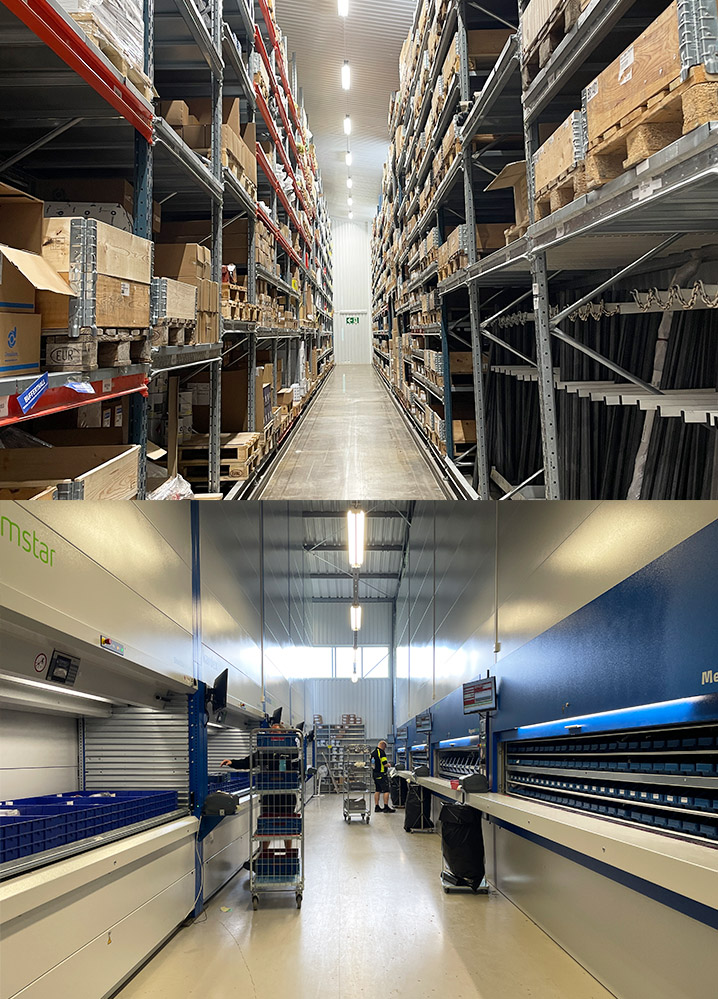

However, the number of parts held in stock increased in line with the recruitment of new members of staff, and after just a couple of years Kaj had outgrown his new building – it was time for the first of several extensions. Today, Olsson Parts has many thousand square metres at its disposal. The storage space and the capacity are constantly being expanded, nowadays mainly upwards, with the aid of modern, ergonomic product hoists.– We now stock more than 30,000 different parts, which is many thousands more than we did three decades ago. At that time, we had one freight provider on one market, whereas now we have seven world-leading freight providers on five markets, states Patrick Winter, Warehouse and Logistics Manager.

A large warehouse places considerable demands as regards good warehouse logistics, and optimisation and stock management are constantly being tightened up, both physically and administratively. Patrick believes that this is a major part of the recipe for success:

– Committed and knowledgeable employees, along with modern warehouse logistics where we prioritise the processing of orders on the same day, are crucial for our success. We have introduced two shifts in order to handle more orders per day. As a result, we are able to pack and dispatch an average of 900 packages every day.